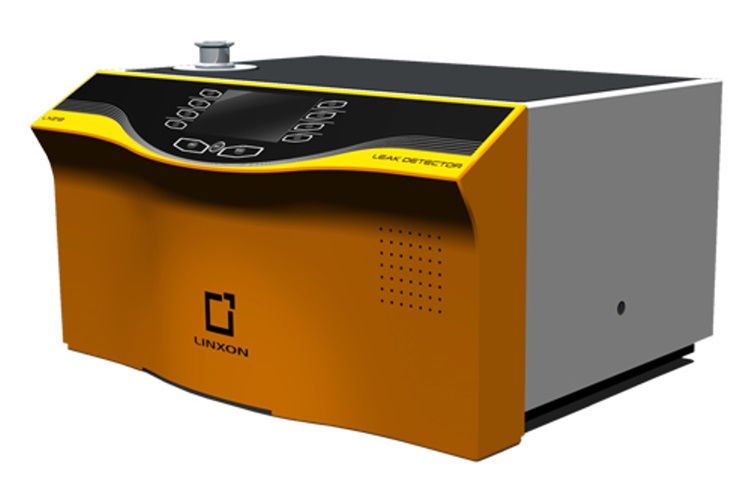

Helium Leak Detector LINXON LX218

Helium Leak Detector

LINXON LX218

Helium Leak Detector

LINXON LX218

The high-performance LINXON LX218 leak detector features reliable technology together with low investment costs. With proven components produced in high volume by global market leader INFICON and lean distribution structures, top-quality performance is possible at a competitive price.

Leak detection is easier than ever before with the LX218’s simple installation and operation. The high suction capacity of the LX218 results in extremely short testing times. This increases your productivity with simultaneous cost efficiency.

The LINXON LX218 leak detector offers many advantages for particularly fast and easy vacuum leak testing. With its robust, modular design and additional accessories, the LX218 offers the greatest flexibility and reliability.

High application flexibility due to LX218 variants:

LINXON LX218 Advantage:

Competitive price thanks to standard components and direct distribution channels

Highest degree of availability and reliability, even after long periods of use, with proven vacuum technology components such as mass spectrometers, pumps and valves

Very short measuring times due to high suction capacity

Detection of the smallest leaks, even in environments contaminated by helium, with an intelligent stainless steel vacuum system

The highest quality in your production or service application guaranteed by high-precision INFICON measuring technology

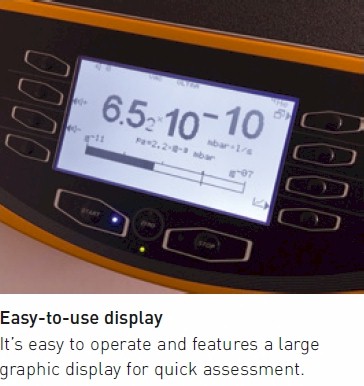

Easy operation and installation, with no training required

Robust and versatile, it can be used even in the harshest production environments

| TECHNICAL DATA | |

|---|---|

| Lowest detectable leak rate for He (according to AVS 2.1) |

‹ 5 x 10-13 Pa m3/s |

| Ion source | Two long-life iridium filaments, yttrium-oxide coated (three-year warranty) |

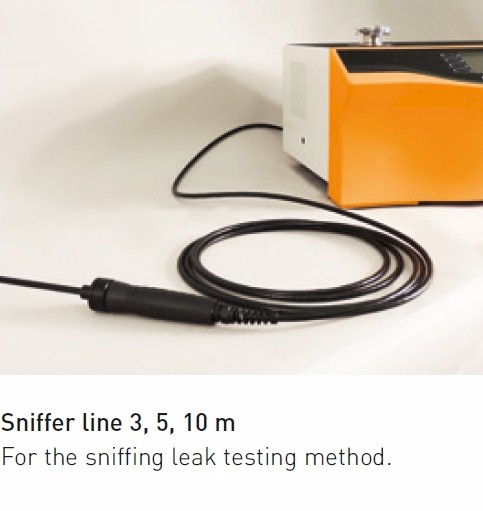

| Testing method | Vacuum and sniffer leak detection |

| Detectable gases | 4He, 3He, H2 |

| Internal He test leak | 10-8 Pa m3/s |

| Leak rate display | 10-13 – 0.1 Pa m3/s |

| Time to operation | 3 min. |

| Response time | 0.5 s |

| Suction capacity: He | 2.5 l/s |

| Connecting flange | DN 25 ISO-KF |

| Inlet pressure, max. | 25 mbar |

| Ambient temperature | +10°C to +35°C in operation |

| Input: analog | Compact gauge |

| Input: digital | Start/stop, zero, calibration |

| Interface | RS-232-C, RS-485 |

| Output: analog | Leak rate signal 2 x 0-10 V, lin/log |

| Output: digital | Ready to start, ready to measure, leak, error, partial flow valve |

| Relay: switch voltage | 2 x 230 V AC |

LINXON LX218 Accessories:

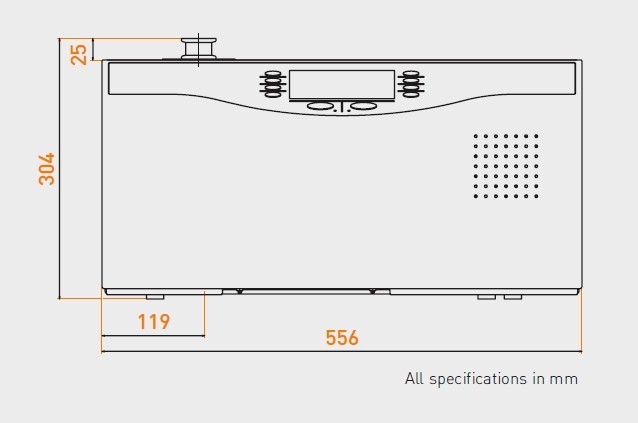

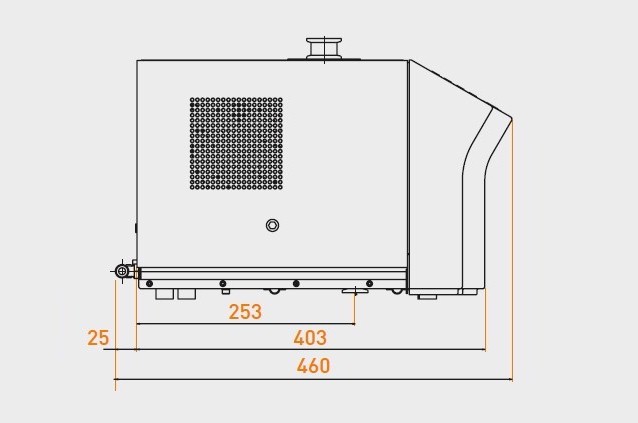

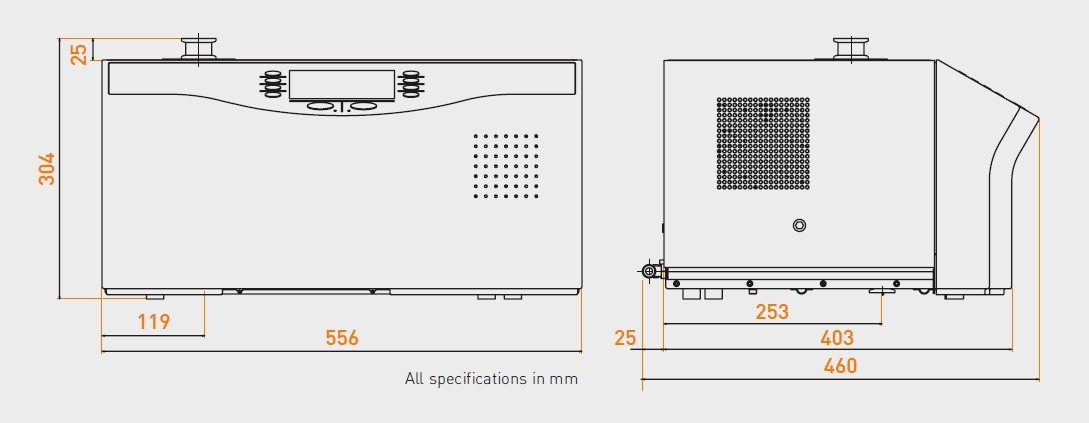

LINXON LX218 Dimensions:

LINXON LX218 Dimensions: